Facts

Show comparison list

Surface cleanliness

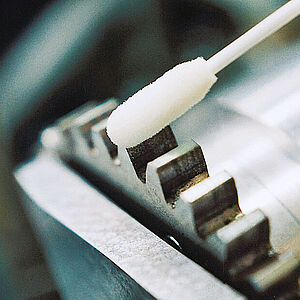

Grip

Elongation

Endotoxin pollution

Ion-free

Cytostatics compatible

Chemical protection

sterile

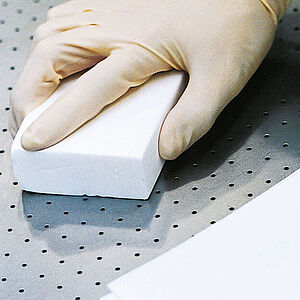

textured

hand specific

Nitrile-polychloroprene mixture

SHIELDskin™ ORANGE NITRILE™ 300 Sterile, Art.-No. 3828

Material: Nitrile-polychloroprene mixture

Properties

- nitrile / polychloroprene mixture

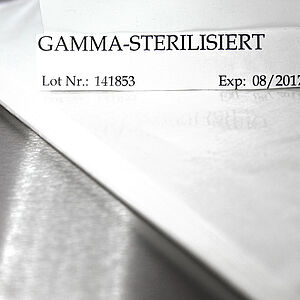

- sterile

- packed in pairs in foil

- ambidextrous

Advantages

- adequate surface cleanliness

- very high elasticity

- high permeation time with disinfectants

- tested with cytostatics

- very high tear resistance

Application

- sterile production / aseptic filling

- for cleaning / disinfection with disinfectants and biocides

- for the production of cytostatics

- for heavy mechanical stress

Product recommendation based on cleanroom classes

Air cleanliness class EN ISO 14644-1

particulate monitored areas

Hygiene zones according to GMP

microbiologically monitored areas

PPE

Personal protective equipment

Regulation (EU) 2016/425

A one-to-one classification of cleanroom gloves to a cleanroom class according to ISO 14644-1 is not possible. Recommendations can only be made based on cleanroom specific requirements, e.g. "abrasion resistance" or "particle emission". In the VDI guideline 2083 Part 9.2 the user can find additional information.

Technical data

| Unit of measurement | Value | Test method | ||

| Material |

Nitrile (NBR)/ Polychloroprene (CR) | |||

|

Perforation-free1 AQL value as defined in ISO 2859-1 for attribute testing on samples | AQL1 | 0.25 Level 3 | ISO 374-2:2019 | |

| Tear resistance |

before ageing after accelerated ageing | N min/typical |

≥ 6.0/10.0 ≥ 6.0/8.0 |

EN 455-2:2015 ASTM D573-04(2019) ASTM D412-16 |

| Extreme elongation |

before ageing after accelerated ageing |

% min |

≥ 500 ≥ 400 |

EN 455-2:2015 ASTM D573-04(2019) ASTM D412-16 |

|

Dimensions nominal single wall thickness |

middle finger palm cuff | mm |

0.17 0.14 0.10 | ASTM D3767-03(2020) |

| Length | mm min/typical | ≥ 290 300 | EN 455-2:2015 | |

|

Size/palm width nominal (+/- 5 mm) |

XS / 6 S / 7 M / 8 L / 9 XL / 10 XXL / 11 | mm |

≤ 80 85 95 105 ≤110 | EN 455-2:2015 |

|

Size/Hand circumference nominal |

XS / 6 S / 7 M / 8 L / 9 XL / 10 XXL / 11 | mm |

152 178 203 229 254 | EN ISO 21420:2020 |

| Biocompatibility | passed |

ISO 10993-10:2010 Tests after irritation and skin sensitization | ||

| Extractable particles | > 0.5 µm |

fixed typical number/cm2 |

n.s. < 3,000 | IEST-RP-CC005.4 |

| Extractable substances | Ions Ammonium (NH4+) Bromide (Br-) Calcium (Ca+) Chloride (ClO2-) Copper (Cu+) Fluoride (F-) Iron (Fe+) Lithium (Li+) Magnesium (Mg+) Nitrate (NO3-) Nitrite (NO2-) Phosphate (PO43-) Potassium (K+) Sodium (Na+) Sulphate (SO42-) Zinc (Zn+) |

µg/cm2 specific n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. |

µg/cm2 specific n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. n.s. | IEST-RP-CC005.4 |

|

Endotoxins detected by LAL test, kinetic turbidimetric |

Endotoxin units (EU) per pair | < 20 | EN 455-3:2015 | |

|

Silicones, amides, Di-n-octylphthalate (DNOP) | not detectable |

IEST-RP-CC005.4 FTIR test procedure | ||

|

Powder residues on the surface |

mg/glove typical | approx. 1.0 – max. 2.0 | ISO 21171:2006 | |

| Vulcanisation accelerators | free | reduces the risk of contact dermatitis (type IV allergy/chemical allergy) | ||

|

Gamma irradiated Sterility Acceptance Level (SAL) |

10-6|

ISO 11137:2015

| | ||

| Non volatile residues (NVR) | µg/g | n.s. | IEST-RP-CC005.4 | |

|

ESD properties surface resistance contact resistance charge decay electrostatic properties (design + material requirements) |

tested | EN 1149-1:2006 EN 1149-2:1997 EN 1149-3:2004 EN 1149-5:2018 | ||

|

Permeation resistance of medical gloves for chemotherapeutics | tested | ASTM D6978-05(2019) | ||

| PU |

20 PE peel off pouches with 1 pair each, in a sealed poly bag | |||

| Carton quantity |

160 pairs 8 sealed poly bags per PE outer bag |