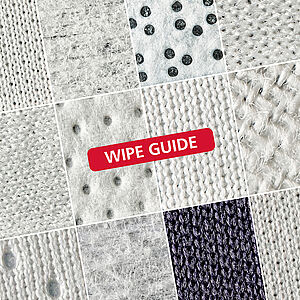

For the selection of a suitable textile only recommendations can be given. The definition of cleanroom textiles essentially depends on the process requirements of the respective end user. Customers in the semiconductor sector have different requirements than customers in the life sciences sector. However, the requirement profiles can also differ significantly in the individual application areas. The specification of the actual air cleanliness class (according to ISO 14644-1) or a hygiene zone (according to GMP) is in most cases not sufficient for an optimised definition alone.

The graphic representation should give you a quick overview of the respective technical properties for comparison.

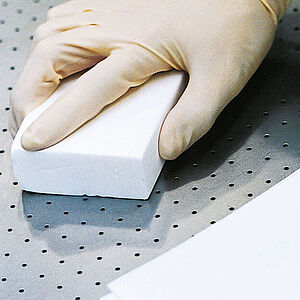

In the end, of course, the model and the detailed designs also determine the respective properties of the cleanroom garments as an overall system. The more uniform the coloured area in the diagram, the more balanced the fabric. For a multitude of applications, however, it is not absolutely necessary for a cleanroom textile to have optimum individual values in all properties. If the process does not demand a very high particle retention capacity under controlled conditions, this is often accompanied by a higher water vapour permeability and thus offers the wearer improved wearing comfort.