The cleanroom fabric ION-NOSTAT VI.2 WA basically has the same fabric characteristics as ION-NOSTAT VI.2. Additionally ION-NOSTAT VI.2 WA offers water repellence (PTFE finish).

All other fabric features are identical to ION-NOSTAT VI.2. These include very good filtration values, a very pleasant wearing comfort (high breathability and pleasant tactile sensation/haptics), good antistatic characteristics as well as a low roughening disposition respectively high abrasion resistance.

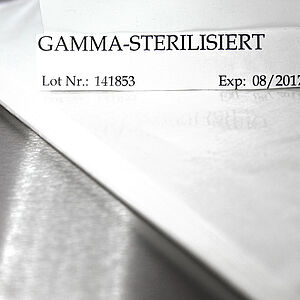

Even with its water repellent outer PTFE-finish, ION-NOSTAT VI.2 WA can be sterilized without any problems.

Fabric properties Important properties at a glance

- LAir Permeability

- TWearing comfort

- PParticle retention capacity

- EElectrostatic behaviour

- AAbrasion resistance

Available colors

Product recommendation based on cleanroom classes

Air cleanliness class EN ISO 14644-1

particulate monitored areas

Hygiene zones according to GMP

microbiologically monitored areas

Technical data

| (3) Fabric | 98% polyester, 2% carbon with polytetrafluorethylene (PTFE) finish (water-repellent) |

|---|---|

| (3) Distances of the electrically conductive yarn | in warp and weft at 5 mm intervals |

| (3) Weave type | 3/2 twill |

| (3) Conductive material/yarn | carbon fibre, sandwich construction |

| (3) Mass per unit area | approx. 113 g/m2 |

| (1) Air permeability according to DIN EN ISO 9237:1999-12 at 200 Pa | 32.7 L/(dm2 x min) |

| (2) Water-vapour resistance DIN EN ISO 11092:2014-12, Ret = m2 Pa/W | Ret 3.1 (good) |

|

(1) Particle retention capacity (VDI 3926)against airborne particles Test duration: 60 minutes Raw gas concentration: 25 mg/m3 |

≥ 0.5 μm approx. 92 % ≥ 5.0 μm approx. 96 |

| (1) Triboelectric behaviouraccording to DIN EN 1149-3 method 1 (ITV-TEV method) | good |

| (3) Surface resistivity according to DIN EN 1149-1:2006-09Protective clothing - Electrostatic properties - Part 1: Test method | 107 - 109 Ohm |

| (1) Abrasion resistance following DIN EN ISO 12947-4Martindale method - assessment of appearance change | very low - low |

The above-mentioned data are the results of investigations carried out by neutral textile research institutes and our suppliers to the best of their knowledge. They are not specifications but typical values at the time of publication.

All statements are without guarantee and changes are possible without prior notice.

Due to different test methods depending on the respective manufacturers and test institutes, the majority of the stated values cannot be compared one-to-one with those of other cleanroom fabrics.

(1) Values determined by the Institute for Textile and Process Engineering Denkendorf

In May 2017 the ITV Denkendorf merged into the public trust DITF Denkendorf.

(2) Values determined by the Hohenstein Textile Testing Institute (HTTI)

(3) Manufacturer information

Test results after 50 decontamination cycles.

Synthetic fabrics can shrink up to 3% during the decontamination process.

If such a textile is additionally autoclaved, the shrinkage has an even stronger optical effect due to the associated formation of wrinkles.

Version 09/2019