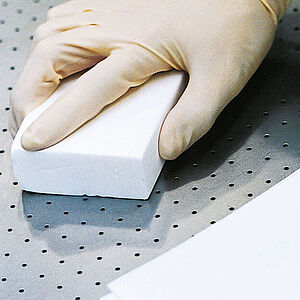

The validated sterile version of the Series 302, a polyester cellulose non-woven wipe, is versatile, both in microbiological controlled zones and in purely particulate controlled areas. Although made of a non-woven fabric, the wipe is characterized by a certain abrasion and tear resistance (even when moist).

The material of the wipe combines the different strengths of cellulose (➜ absorbency) and polyester fibre (➜ abrasion resistance) and is therefore also a happy medium in terms of costs. The hydro-bonded non-woven fabric is, in direct comparison to the series 300 and 303, cleaner.

Facts

Polyester-cellulose

Non-woven, 45% PES / 55% CEL, hydroentangled, validated sterile

Properties

- 45% polyester / 55% cellulose

- hydro-entangled non-woven fabric

- validated sterile

- low particle and fibre emission

- relatively abrasion resistant

- good absorptive capacity

- double bag packing

Advantages

- good chemical compatibility with different solvents and cleaning agents

- one of the purest polyester-cellulose non-woven wipes

- multipurpose

Applications

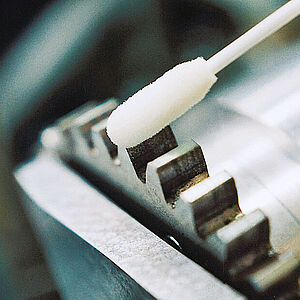

- all-purpose wipe partly also for more sensitive areas

- absorbency of liquids and spills

- also for the cleaning of (particulate) more critical areas (when pure polyester wipes cannot be used)

- workplace cleaning – especially for smooth surfaces

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value/ | Test method/ | |

|---|---|---|---|---|

| Material | 45% PES / 55% CEL | |||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 | 68 | ||

| Thickness | mm | 0.30 | ||

|

Absorptive capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | 5.1 335 | IEST-RP-CC004.3 | |

|

NVR Non-volatile residues |

IPA based DI water based |

g/m2 g/m2 |

0.073 0.097 | IEST-RP-CC004.3 |

| Particulate residues |

0.5 – < 5.0 µm > 5.0 – ≤ 100 µm |

x 106/m2 x 106/m2 |

88 1.2 |

IEST-RP-CC004.3 Section 6.1.3 Biaxial Shake Test |

| Fibre residues | > 100 µm | fibres/cm2 | 45,550 |

IEST-RP-CC004.3 Section 6.2.2.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

87 35 |

IEST-RP-CC004.3 Section 7.2.2.1 |

| Endotoxins | limit < 20 I.U./wipe |

pH 6.0 - 8.0 Recovery rate of the Positive Product Control (PPC)50 - 200% 94% |

corresponds < 0.50 I.U./ml 0.024 I.U./ml |

Ph. EUR. 2.6.14 LAL test, kinetic turbidimetric method (method C) |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

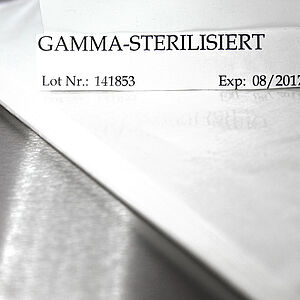

| Sterilisation | validated sterile |

Sterility Assurance Level (SAL) | 10-6 |

AAMI/ISO 11737 Sterilization of health care products – Microbiological methods – Part 1: Determination of a population of microorganisms on products |

| Size | PU/Carton | subpacked | Art. No. | |

|

6" x 6" 9" x 9" 12" x 12" 18" x 18" |

2,000 1,800 600 375 |

10 x 200 wipes (8 x 25 wipes) 12 x 150 wipes (6 x 25 wipes) 4 x 150 wipes (6 x 25 wipes) 5 x 75 wipes (3 x 25 wipes) |

57302 0606 57302 0909 57302 1212 57302 1818 | |

| n. s. = not specified n. d. = not detectable |

Note