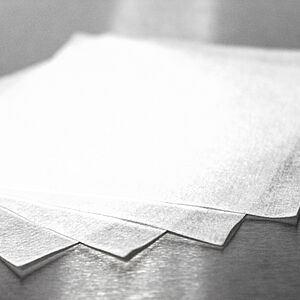

De Contec® Critical Site® Sterile Wipes zijn steriele dokjes, van waterstraal verdicht polyestervlies, geïmpregneerd met 70% IPA / 30% gedeïoniseerd water. Dankzij het kleine formaat zijn ze bijzonder geschikt voor verschillende natte reinigingstaken in gebieden waar enerzijds gevalideerde steriliteit en deeltjesreinheid vereist zijn, en anderzijds kleine en moeilijk toegankelijke oppervlakken, zoals fiolen te vinden zijn.

Ze zijn verpakt in een gebruiksvriendelijke, hersluitbare platte zak, ontworpen voor een grotere behoefte aan doekjes per gebruik.

Feiten en cijfers

Getränkte Tücher

Non-woven, 100% PES, impregnated with 70% IPA / 30% DI water, validated sterile.

Properties

- hydroentangled non-woven fabric made of 100% polyester

- saturated with 70% IPA / 30% DI water

- validated sterile (SAL at 10-6)

- particulate clean

Advantages

- small wipe needed in larger quantities per use

- good chemical resistance

- reduced levels of volatile organic compounds (VOC)

- low-cost version compared to knitted wipes

- fast-drying disinfection

- storage costs for cleaning agents and time-consuming ancillary work such as decanting, spraying and wetting are eliminated

- resealable bag ensures constant solvent saturation during use

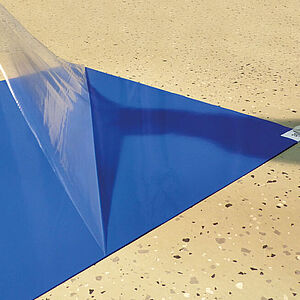

- space-saving, ideal for isolators or unidirectional airflow cabinets (UDAF)

Applications

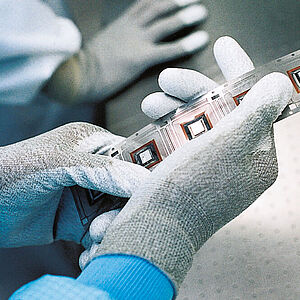

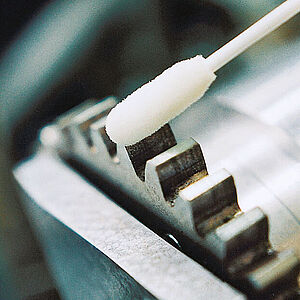

- ideal for wiping the top of vials prior to piercing the septum for reconstitution or use

- pharmaceutical industry

- medical devices and equipment

- cleaning of parts of insulators or barrier systems with restricted access (RABS)

- removing contamination from the workplace and during maintenance work

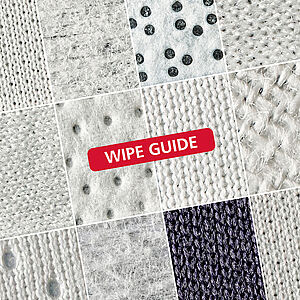

Productkeuze op basis van de cleanroomklassen

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technische gegevens

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material (fabric) |

100% PES hydroentangled | |||

| Saturation solution |

70% IPA / 30% DI water | |||

| Edge processing | cut | |||

| Mass per unit area | g/m2 | 67 | ||

| Thickness |

mils mm |

n.s. n.s. | ||

|

Non-volatile residues NVR |

IPA based DI water based |

ppm ppm |

0.008 0.055 |

IEST-RP-CC004.3, Sec. 7.1.2 IEST-RP-CC004.3, Sec. 7.1.2 |

| Particle residues | > 0.5 µm | x 106/m2 | 39.3 | IEST-RP-CC004.2, Sec. 5.1 |

| Fibre residues | > 100 µm | x 103/m2 | 10.4 | IEST-RP-CC-004.2, Sec. 5.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

2.16 9.35 |

IEST-RP-CC004.3 IEST-RP-CC004.3 |

| Sterilisation | validated sterile | SAL (10-6) | yes |

AAMI ISO 11737-1 Sterilization of health care products - Radiation |

| Dimensions | PU per case | Art. no. | ||

|

4" x 4" (~ 10 x 10 cm) |

1,440 pieces (60 pcs./pouch) | 59802-01 |

Let op