Model selection

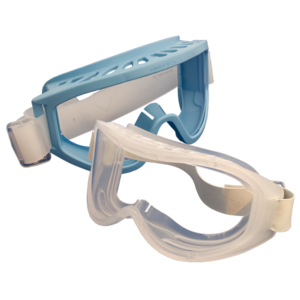

The model variety of cleanroom safety goggles has increased significantly due to growing importance and regulatory requirements. Typical differentiation criteria are:

Cleanroom protection goggles with direct ventilation

Here the air can reach the lenses inside unhindered, usually from above. A major advantage: the lenses fog up less. Disadvantage: Contamination can escape unhindered via the large openings.

Cleanroom protection goggles with indirect ventilation

With these frame constructions, the air only enters the goggles via "detours". The risk of contamination, e.g. hair or skin scales escaping, is thus significantly lower. However, these goggles often fog up more quickly. But then, when cleaning overhead with detergents or disinfectants, they offer significantly better protection against the unwanted entry of liquids.

Cleanroom protection goggles with anti-fogging equipment

Especially for protection goggles with indirect ventilation, goggles lenses with special coatings against fogging are recommended. However, these lenses with such special options have to be replaced more frequently, as the coatings are affected more quickly by the cleaning, disinfection or sterilisation processes.

Important parameters for the evaluation of the individual suitability of cleanroom protection goggles are amongst others:

- ventilation system in the frame

- surface treatment for lense (e.g. anti-fog and scratch-resistant)

- autoclavability

- tendency to deform

On request, the adjustable bands of some goggles can be replaced by a strap to reduce the pressure the straps exert!

Spare lenses and bands on request!

We are expanding our product range – if you are interested, please contact us!

indirect ventilation top

scratch proof

indirect ventilation

direct ventilation top

direct ventilation top

scratch proof

BCAP

indirect ventilation

scratch proof

direct/indirect ventilation at the top, indirect below

scratch proof

direct ventilation at the top, sealed bottom

scratch proof

direct ventilation at the top, sealed bottom

scratch proof

Product recommendation based on cleanroom classes

Air cleanliness class EN ISO 14644-1

particulate monitored areas

Hygiene zones according to GMP

microbiologically monitored areas

PPE

Personal protective equipment

Regulation (EU) 2016/425