Facts

Show comparison list

Surface cleanliness

Grip

Elongation

Endotoxin pollution

Ion-free

Cytostatics compatible

Chemical protection

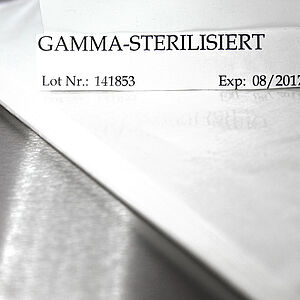

sterile

textured

hand specific

Nitrile

SHIELDskin XTREME™ White Nitrile 300 DI, Art.-No. 3823

Material: Nitrile

Properties

- 100% nitrile

- powder-free

- packed in bags

- ambidextrous

Advantages

- satisfactory surface cleanliness

- low clearance of ions

- conductive

- high permeation time for chemicals

- good mechanical resilience

Application

- for normal process requirements

- for working with chemicals

- for heavy mechanical stress

Product recommendation based on cleanroom classes

Air cleanliness class EN ISO 14644-1

particulate monitored areas

Hygiene zones according to GMP

microbiologically monitored areas

PPE

Personal protective equipment

Regulation (EU) 2016/425

A one-to-one classification of cleanroom gloves to a cleanroom class according to ISO 14644-1 is not possible. Recommendations can only be made based on cleanroom specific requirements, e.g. "abrasion resistance" or "particle emission". In the VDI guideline 2083 Part 9.2 the user can find additional information.

Technical data

| Unit of measurement | Value | Test method | ||

|

Material |

100% nitrile Nitrile Butadiene Rubber | |||

|

Perforation free1 AQL value as defined in ISO 2859-1 for attribute testing on samples | AQL1 | 1.5 Level 2 | ISO 374-2:2019 | |

| Tear resistance |

before ageing after accelerated ageing | N spec/typical |

≥ 6.0/9.0 ≥ 6.0/8.0 |

EN 455-2:2015 ASTM D573-04(2015) + ASTM D412-16 |

| Extreme elongation |

before ageing after accelerated ageing |

% spec |

≥ 500 ≥ 400 |

EN 455-2:2015 + ASTM D412-15a ASTM D573-04(2015) |

|

Dimensions nominal single wall thickness |

middle finger palm cuff | mm (+/- 0.03 mm) |

0.15 0.13 0.10 | ASTM D3767-03(2014) |

|

Length tip of the middle finger to the cuff | mm min/typical | ≥ 285/300 | EN ISO 21420:2020 | |

|

Size/palm width nominal |

XS / 6 S / 7 M / 8 L / 9 XL / 10 XXL / 11 | mm (+/- 5 mm) |

≤ 80 85 95 105 115 ≥ 120 | EN 455-2:2015 |

|

Size/Hand circumference nominal |

XS / 6 S / 7 M / 8 L / 9 XL / 10 XXL / 11 | mm |

152 178 203 229 254 279 | EN ISO 21420:2020 |

| Extractable particles | ≥ 0.5 µm |

number/cm2 specification typical | < 3,000 2,300 | IEST-RP-CC005.4 |

|

Endotoxins detected by turbidimetric kinetic LAL test |

Endotoxin units (EU) per pair | < 20 | EN 455-3:2015 | |

|

Silicones, amides, Di-n-octyl phthalate (DNOP) | not detectable |

IEST-RP-CC005.4 FTIR Method | ||

|

Powder-free on the surface |

single washed in DI water | ISO 21171:2006 | ||

| Biocompatibility | evidenced by |

Modified epicutaneous test according to Buehler + Primary skin irritation tests | ||

| Chemical allergens | not detectable | High Performance Liquid Chromatography test method for quantitative analysis + aqueous phosphate solution extraction | ||

| Vulcanisation accelerators | free | produced without thiazoles and thiurams | ||

| Extractable substances | Ions Ammonium (NH4+) Bromide (Br-) Calcium (Ca+) Chloride (ClO2-) Copper (Cu+) Fluoride (F-) Iron (Fe+) Lithium (Li+) Magnesium (Mg+) Nitrate (NO3-) Nitrite (NO2-) Phosphate (PO43-) Potassium (K+) Sodium (Na+) Sulphate (SO42-) Zinc (Zn+) |

µg/cm2 specification 0.050 0.030 1.000 0.600 n.s. 0.010 n.s. n.s. 0.010 0.600 0.050 0.050 0.150 0.150 0.200 n.s. |

µg/cm2 typical value < 0.008 < 0.008 0.700 0.300 n.s. < 0.008 n.s. n.s. < 0.008 0.230 < 0.008 < 0.008 0.050 0.040 0.130 n.s. | IEST-RP-CC005.4 |

| Electrostatic properties (ESD) | passed | EN 1149-1/2/3/ & 5 | ||

| Non volatile residues (NVR) | mg/g | ≤ 30 | IEST-RP-CC005.4 | |

| PU |

100 pieces flat packed in a welded PE inner and outer bag | |||

| Cardboard quantity |

1,000 pieces 10 PE outer bags of 100 pieces each |