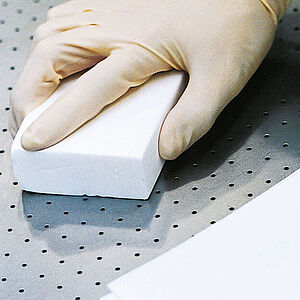

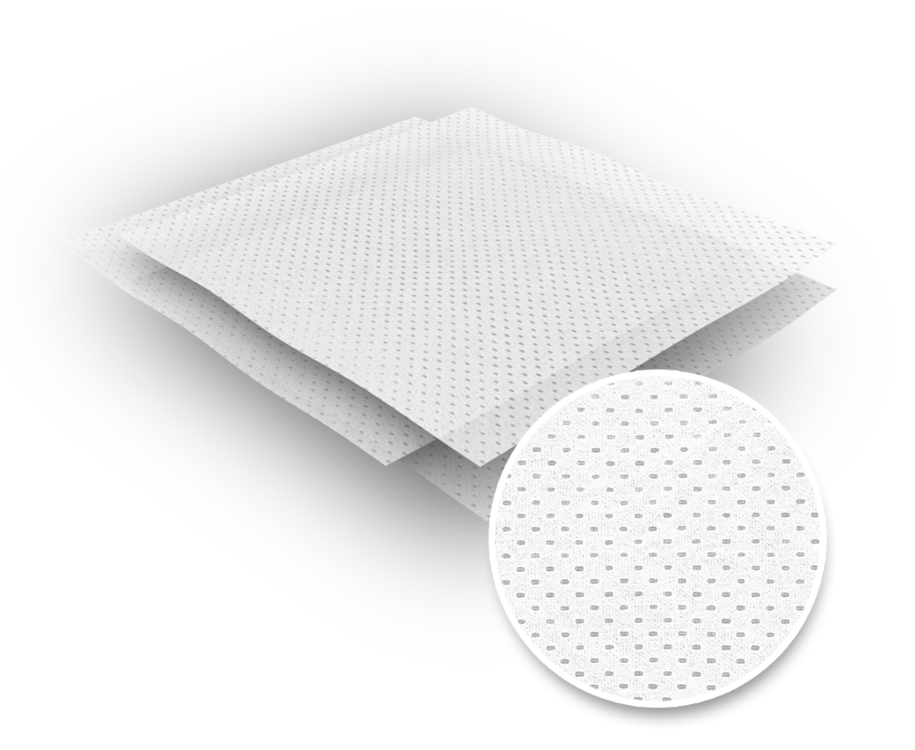

The gamma irradiated version of the series 410-AF, a 100% polyester wipe knitted from filaments, is one of the most efficient cleanroom wipes for more critical areas, both in microbiological controlled and purely particle controlled zones. The cloth is cut by ultrasound and thus the edges are sealed. After cutting, the wipes are professionally cleaned and packed in a cleanroom laundry. Even though they are made of 100% polyester, the double-layer wipes have a good absorption capacity. However, the liquid stored in the wipe is also evenly released back to a surface when required, which is why the series 410-AF enjoys particular popularity in the pharmaceutical sector (in combination with disinfectants). The robust polyester knitted fabric shows its strength on rougher surfaces or on sharp-edged objects and/or surfaces. Due to the cleanroom-compatible post-cleaning, the wipes have relatively low levels of ionic and metallic contamination.

Facts

Polyester

Knit, 100% PES filaments, double layer, ultrasonic-sealed edges, gamma-irradiated.

Properties

- 100% polyester, two-ply knitted wipe ultrasonically welded, continuous filaments

- edges cut and sealed by ultrasound

- clean and abrasion resistant

- decontaminated in a cleanroom laundry

- double bag packed in a cleanroom (air cleanliness class ISO 4)

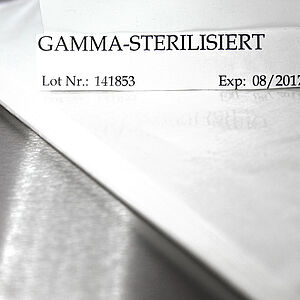

- gamma-irradiated

Advantages

- good absorption capacity due to the double-knit construction

- extremely low emission of own particles

- reduced fibre release due to the sealed edges

- low ionic and metallic impurities

Applications

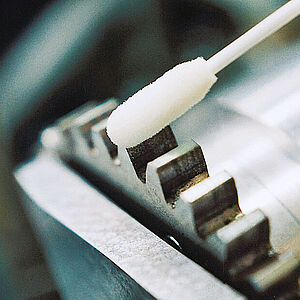

- cleaning wipe especially for critical areas

- cleaning wipe for areas where high absorbency and cleanliness are required

- well suited for angular, rough surfaces and objects that might prematurely damage a non-woven fabric wipe

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 100% PES | |||

| Edge processing | ultrasonic cut | |||

| Mass per unit area | g/m2 ± 5% | 265 | ||

| Thickness | mm ± 5% | 0.87 | ||

|

Absorptive capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | 3.24 858 | IEST-RP-CC004.3 | |

| Absorbency rate | second | < 1 | IEST-RP-CC004.3 | |

|

NVR Non-volatile residues |

IPA based DI water based |

µg/m2 µg/m2 |

1.66 n. s. | IEST-RP-CC004.3 |

| Particulate residues | ≥ 0.5 µm | 103/cm² | 0,495 |

IEST-RP-CC004.3 performed by Liquid-borne Particle Counter (LPC) |

| Fibre residues | > 100 µm | fibres/m2 | n. s. | IEST-RP-CC004.3 |

| Ionic residues |

Aluminium (Al-) Calcium (Ca+) Iron (Fe+) Lithium (Li+) Magnesium (Mg+) Nitrate (NO3-) Nitrite (NO2-) Phosphate (PO43-) Potassium (K+) Sodium (Na+) Sulphate (SO42-) |

µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² µg/cm² |

n. s. 0.001 n. s. n. d. 0.001 n. d. n. s. n. s. 0.001 0.011 0.004 |

IEST-RP-CC004.3 performed by Inductively Coupled Plasma Mass Spectrometry (ICP-MS) |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. d. n. d. n. d. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Sterilisation | Gamma radiation | kGy | 25 – 40 | DIN EN ISO 11137-1 |

| Size | PU/Carton | subpacked | Art. No. | |

|

9" x 9" (~ 23 x 23 cm) 12" x 12" (~ 30 x 30 cm) |

100 800 |

2 x 10 bags à 5 wipes 8 bags à 100 wipes (4 x 25) |

57410-AF-5S 57410-AF | |

| n. s. = not specified n. d. = not detectable |

Note