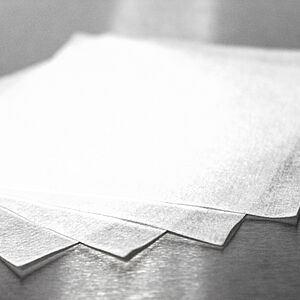

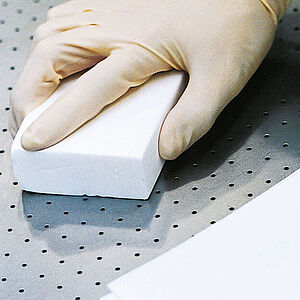

The wipe PROSAT® Sterile™ PS-7030IR from CONTEC® uses a high-quality non-woven fabric from DuPont™. It is currently one of the cleanest non-woven wipes on the market. The 100% hydroentangled polyester non-woven fabric is extremely soft, clean and durable.

The pre-saturated wipes are gamma-irradiated according to AAMI guidelines. They have low values of particles and extractable substances. The wipes are packed in a flat, reclosable pouch with a tamper-proof label.

Facts

Saturated wipes

Non-woven, 100% PES, with 70% IPA / 30% DI water, validated sterile

Properties

- 100% polyester

- hydroentangled non-woven fabric

- saturated with 70% IPA/30% DI water (USP quality)

- validated sterile (SAL of 10-6)

- resealable PE pouch with a tamper-evident label, packed in a bag and outer bag

Advantages

- low particle and fibre emission

- fast and efficient cleaning

- reduces the storage of cleaning agents

- easier to transport, store and use

- even application of the cleaning solution

Applications

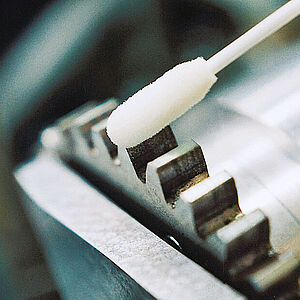

- wiping of objects before the airlock procedure

- for quick and practical surface cleaning of equipment and parts

- wet cleaning of scratch-sensitive surfaces to specifically remove chemical residues

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material (fabric) | 100% PES | |||

| Saturation solution | 70% IPA (USP grade) / 30% deionised water | |||

| Edge processing | cut | |||

| Mass per unit area | g/m2 | 67 | ||

|

Non-volatile residues NVR |

IPA based DI water based |

g/m² g/m² |

0.008 0.055 |

IEST-RP-CC004.3, Sec. 7.1.2 IEST-RP-CC004.3, Sec. 7.1.2 |

| Particle residues | ≥ 0.5 µm | x 106/m2 | 39.3 | IEST-RP-CC004.2, Sec. 5.1.2 |

| Fibre residues | > 100 µm | x 103/m2 | 10.4 | IEST-RP-CC004.2, Sec. 5.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

1.9 4.7 |

IEST-RP-CC004.3, Sec. 7.2.2 IEST-RP-CC004.3, Sec. 7.2.2 |

| Sterilisation | Gamma radiation | yes | AAMI Guidelines | |

| Dimensions | PU in a case | Art. no. | ||

|

9" x 9" (~ 23 x 23 cm) |

800 pieces 20 pcs./Pouch | 59803 |

Note