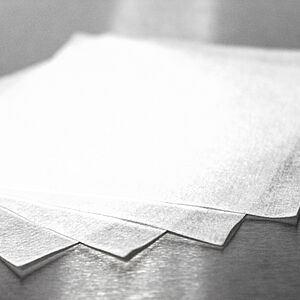

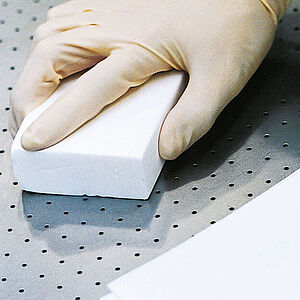

KIMTECH™ PURE W4, our 704 series, is a high performance wipe made from 100% polypropylene, whose filaments are thermally bonded – i.e. it is free from adhesives or binders. It is resistant to acids, alkalis and solvents. It is ideal for wiping and absorbing chemicals and solvents on all kinds of surfaces.

Facts

Special requirements

KIMTECH™ W4, melt blown non-woven, 100% PP

Properties

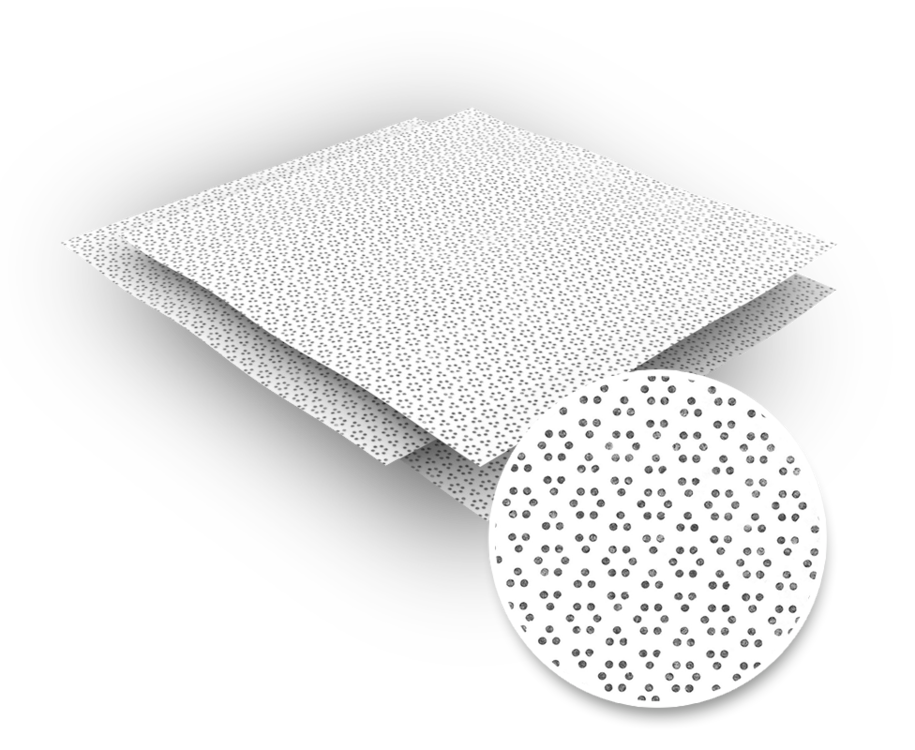

- 100% polypropylene

- meltblown non-woven fabric

- thermally bonded, free of adhesives and binders

- cold cut edges

- single bag packaging

Advantages

- chemically stable

- versatile

- good absorption capacity

- good abrasion resistance

Applications

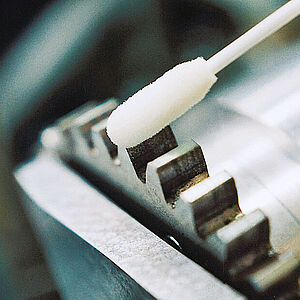

- all-purpose wipe

- removal or application of acids, alkalis and solvents can be carried out in a single wiping operation

- workplace and tool cleaning

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 100% PP | |||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 | 84.8 | ||

|

Absorptive capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | n. s. 445 | IEST-RP-CC004.3 | |

| Absorbency rate | second | 1.4 | IEST-RP-CC004.3 | |

|

NVR Non-volatile residues |

IPA based DI water based |

g/m2 g/m2 |

0.27 0.22 | IEST-RP-CC004.3 |

| Particulate residues |

> 0.5 – < 100 µm |

x 106/m2 |

13 |

IEST-RP-CC004.3 Section 6.1.3 Biaxial shake test |

| Fibre residues | ≥ 100 µm | x 103/m2 | 6.3 |

IEST-RP-CC004.3 Section 6.2.2 Optical (OM) and Scanning Electron Microscopy (SEM) |

| Ionic residues |

Chloride (ClO2-) Potassium (K+) Sodium (Na+) |

ppm ppm ppm |

36.00 5.30 87.90 | IEST-RP-CC004.3 |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Size | PU/Carton | subpacked | Art. No. | |

|

9" x 9" 12" x 12" |

500 500 |

5 bags à 100 wipes 5 bags à 100 wipes |

55704 0909 55704 1212 | |

| n. s. = not specified n. d. = not detectable |

Note