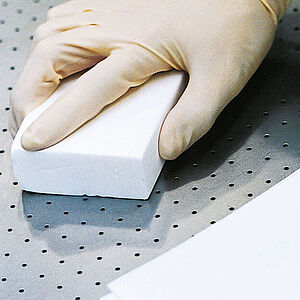

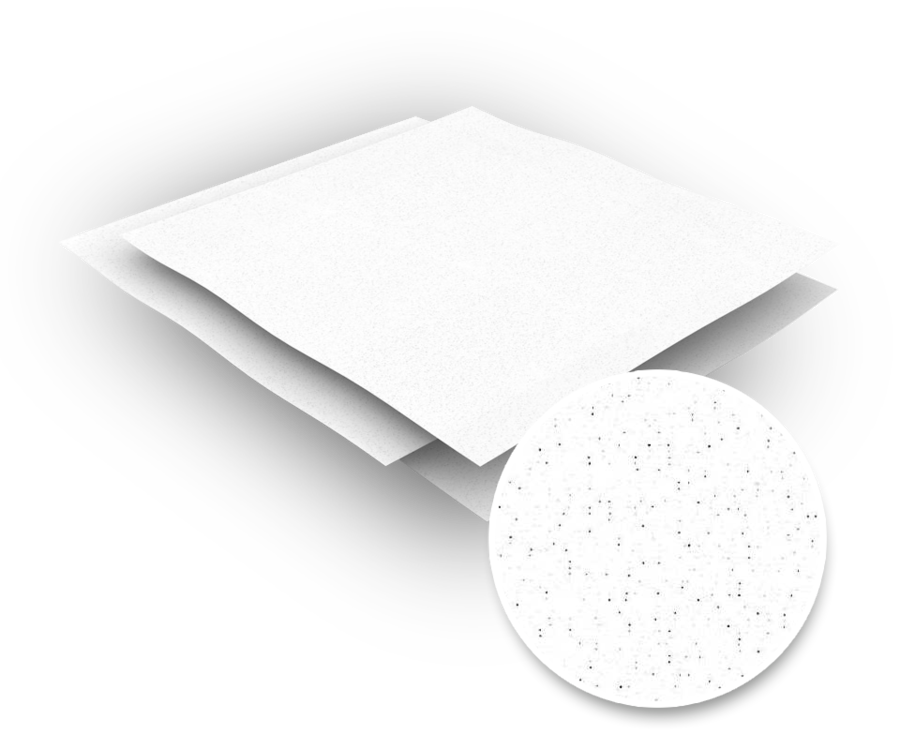

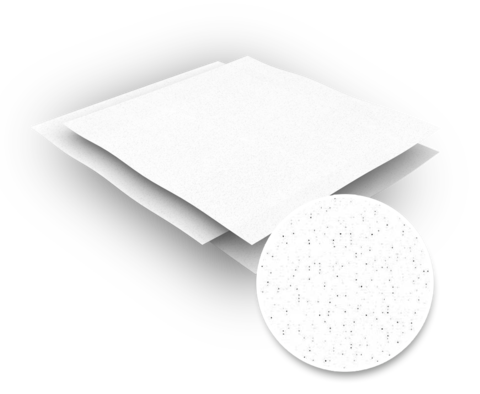

The 429-IO series, a microfibre woven wipe made of polyester and polyamide (70/30), is characterised by very good cleaning performance, even with greasy soiling. Even though it is made only from synthetic fibres, the wipe has sufficient absorption capacity for aqueous solutions. It is chemically resistant to acids (peracetic acid), alkalis (caustic soda, nitric acid), bleaching agents and solvents (isopropanol, acetone, benzene compounds). The wipes are primarily used in clean particulate-controlled areas, but can also be used at any time in microbiologically controlled zones. Cutting is carried out using ultrasound, which seals the edges. After cutting, the wipes are professionally decontaminated in a cleanroom laundry and packaged under ISO class 5 conditions. The wipes have relatively low levels of ionic and metallic contamination thanks to the cleanroom-compatible post-cleaning process.

Facts

Special requirements

Microfibre wipe, woven, 70% PES / 30% PA

Properties

- 70% polyester / 30% polyamide

- woven from microfibre filaments

- ultrasonically cut and sealed edges

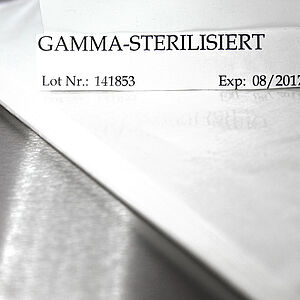

- decontaminated in a cleanroom laundry

- vacuum-packed twice in PE film in a cleanroom

Advantages

- very good cleaning performance due to the elastic and dense weave and the structured surface

- low abrasion even under heavy mechanical load

- high chemical resistance and low abrasion due to the twisted threads

Applications

- effective removal of particulate and organic contamination

- very well suited for wiping highly sensitive surfaces

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 70% PES / 30% PA | |||

| Edge processing | ultrasonic cut | |||

| Mass per unit area | g/m2 | 105 ± 10 |

ASTM D3776 Standard Test Methods for Mass Per Unit Area (Weight) of FabricISO 9073 | |

| Weight (wipe) | g | n. s. | ASTM D3776 | |

| Thickness | mm | n. s. |

ASTM D1777 Standard Test Method for Thickness of Textile MaterialsISO 9073-2 Textiles – Test methods for nonwovens – Part 2: Determination of thickness | |

|

Absorptive capacity Ai intrinsic Ae extrinsic | ml/g ml/m2 | 2.3 240 |

IEST-RP-CC004.3 Section 8.2 | |

| Absorbency rate | sec. | 1 |

IEST-RP-CC004.3 Section 8.2 | |

|

NVR Non-volatile residues |

IPA based DI water based |

g/m2 g/m2 |

0.05 0.02 |

IEST-RP-CC004.3 Section 7 |

| Particulate residues | > 0.5 µm | particles/wipe m2 | 40 x 106 | IEST-RP-CC003.4 |

| Fibre residues | > 100 | fibres/m2 | n. s. | IEST-RP-CC003.4 |

| Ionic residues |

Chloride (ClO2-) Nitrate (NO3-) Potassium (K+) Sodium (Na+) Sulphate (SO42-) |

µg/g µg/g µg/g µg/g µg/g |

1.5 0.8 0.1 1.5 1.0 |

IEST-RP-CC004.3 Section 7 |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DNOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Size | PU/Carton | subpacked | Art. No. | |

|

9" x 9" (~23 x 23 cm) 12" x 12" (~30 x 30 cm) |

2,000 2,000 |

20 bags à 100 wipes 20 bags à 100 wipes |

55429-IO 55429-IO | |

| n. s. = not specified n. d. = not detectable |

Note