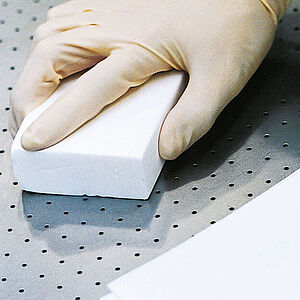

Series 400-AF, a microfibre wipe made of 70% polyester and 30% polyamide, is versatile, both in microbiological controlled areas and in purely particle controlled areas. The hydro-entangled non-woven construction gives the wipe a very high abrasion and tear resistance. In addition, it is free of adhesives and binding agents, which is ultimately reflected in the low extractable residues. Due to the microfibre construction, its strength lies in its cleaning efficiency. In many cases, even difficult soiling can be removed more easily and quickly with relatively little expenditure of time. Compared to the polyester-cellulose non-woven wipes or 100% polyester non-woven wipes, the series 400-AF has a significantly lower particle emission and can definitely compete with knitted polyester wipes.

Facts

Special requirements

Microfibre non-woven, 70% PES/30% PA, water jet consolidated

Properties

- 70% polyester / 30% polyamide

- water-jet compacted microfibre non-woven fabric

- cold cut edges

- packed in a single PE-bag

Advantages

- good absorbency measured by mass per unit area

- abrasion and tear resistant

- good resistance to chemicals normally used in cleanrooms

- soft handle and gentle on scratch-sensitive surfaces

Applications

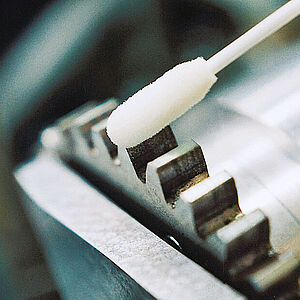

- cleaning wipe especially for critical areas

- cleaning wipe for areas where high absorbency and cleanliness are required

- cleaning wipe for optical surfaces, as well as other similarly sensitive surfaces

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 70% PES / 30% PA |

ASTM D629 Standard Test Methods for Quantitative Analysis of Textiles | ||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 ± 5% | 60 | ||

|

Absorptive capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | n. s. 212.5 |

IEST-RP-CC004.3 Section 8.3 | |

| Absorbency rate | second | 1 |

IEST-RP-CC004.3 Section 8.2 | |

|

NVR Non-volatile residues |

IPA based DI water based |

µg/cm2 µg/cm2 |

n. d. 2.3 |

IEST-RP-CC004.3 Section 7.1 |

| Particle residues |

0.1 – ≤ 0.2 µm > 0.2 – ≤ 0.5 µm > 0.5 – ≤ 1.0 µm > 1.0 µm | number/cm2 |

5,030 4,670 1,470 366 |

IEST-RP-CC004.3 Section 6.1.3 and 6.2.1 Biaxial shake test & per liquid(-borne) particle counter (LPC) |

| Fibre residues | > 100 µm | fibres/cm2 | n.s. |

IEST-RP-CC004.3 Section 6.1.3 and 6.2.1 |

| Ionic residues |

Ammonium (NH4+) Bromide (Br-) Calcium (Ca+) Chloride (ClO2-) Fluorine (Fl-) Iodine (I+) Lithium (Li+) Magnesium (Mg+) Nitrate (NO3-) Nitrite (NO2-) Phosphate (PO43-) Potassium (K+) Sodium (Na+) Sulphate (SO42-) |

µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 µg/cm2 |

0.0033 112 0.0757 n. d. n. d. n. d. n. d. n. d. 0.0216 not tested n. d. 0.0053 0.825 0.424 |

IEST-RP-CC004.3 Section 7.2.2 measured by ion chromatograph |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Dimensions | PU in a bag | PU per carton | ||

|

9" x 10" (~ 23 x 25 cm) | 300 pieces | 12 | ||

| n. s. = not specified n. d. = not detectable |

Note