The textile Light-Tech SW is mainly used for the production of so-called cleanroom-suitable intermediate garments (undergarments).

The low mass per unit area combined with an extremely pleasant feel (silk-like) are the special features of this fabric. Due to the use of conductive fibres in the warp direction, the Light-Tech SW fabric also has antistatic properties.

The antimicrobial finish reduces possible germ growth as well as the often associated odour formation already under the cleanroom outerwear.

Fabric properties Important properties at a glance

Available colors

The evaluation of the textile properties listed here is primarily based on empirical values and only partly on real measured values.

Product recommendation based on cleanroom classes

Cleanroom suitable undergarments made of Light-Tech SW can be worn in any cleanroom class area.

Various studies have shown that the use of a suitable cleanroom-suitable intermediate garment can reduce both the microbiological contamination and the number of possible particulate impurities by 50% and more.

Technical data

| (1) Fabric |

99% polyester, 1% carbon |

|---|---|

| (1) Intervals of the electrically conductive yarn | at 9 mm in warp |

| (1) Material of the electrically conductive yarn | carbon (trilobal cross section), polyester (Nega-Stat® P210 yarn) |

| (1) Weave type | plain weave |

| (1) Mass per unit area | approx. 99 g/m2 |

| (1) Air permeability at 200 Pa | 129 L (dm2 x min) |

| (1) Water-vapour permeability unwashed | 1,350 g/m2 x 24 hrs. |

|

(1) Surface resistivity according to AATTC 76Electrical Resistivity of Fabrics (Reaffirmed - 2011) standard by American Association of Textile Chemists and Colorists | 108 - 109 Ohm |

| (1) Special properties | antimicrobial equipment |

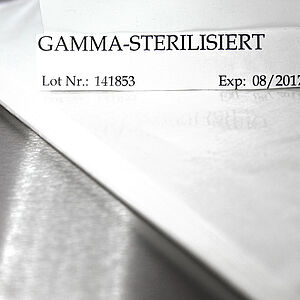

(1) Manufacturer information

The above information is the result of tests carried out by the supplier to the best of his knowledge.

They are not specifications but typical values at the time of publication.

All information is without guarantee and changes are also possible without prior notice.

Due to different testing methods depending on the respective manufacturers and testing institutes, most of the values indicated cannot be compared one-to-one with those of other cleanroom fabrics.

Synthetic fabrics can shrink up to 3% during the decontamination process.

Issue 09/2019