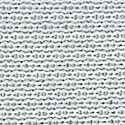

In the development of the high-performance knitted fabric HT3, the main focus was on providing the wearers of cleanroom undergarments with a material that can develop both slightly cooling effects when required, but also has a heat-insulating effect in the opposite direction when necessary. Special hollow fibres (Thermo°Cool Fresh™ technology) are used for this purpose.

Into the synthetic fibres of HT3 silver ions are also firmly (non-migrating) incorporated. Thus, like HT2, HT3 has an antimicrobial effect, i.e. germ growth on/in the textile is hindered and possible odour nuisance is reduced.

With the additional use of elastane fibres, the wearing comfort properties (especially haptics and elasticity) are significantly improved once again.

Fabric properties Important properties at a glance

Available colors

The evaluation of the textile properties listed here is primarily based on empirical values and only partly on real measured values.

Product recommendation based on cleanroom classes

Cleanroom suitable undergarments made of HT3 can basically be worn in any cleanroom class area. Recommended especially under "cooler" ambient conditions.

Various studies have shown that the use of a suitable cleanroom-suitable intermediate garment can reduce both the microbiological contamination and the number of possible particulate impurities by 50% and more.

(1) Manufacturer information

The above information is the result of tests carried out by the supplier to the best of his knowledge.

They are not specifications but typical values at the time of publication.

All information is without guarantee and changes are also possible without prior notice.

Due to different testing methods depending on the respective manufacturers and testing institutes, most of the indicated values cannot be compared one-to-one with those of other cleanroom fabrics.

Synthetic knitted fabrics can shrink by up to 5% during the decontamination process.

Issue 09/2019