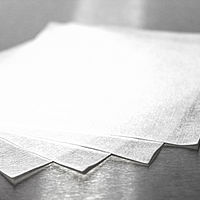

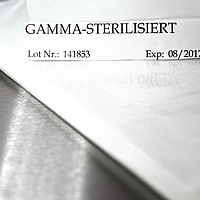

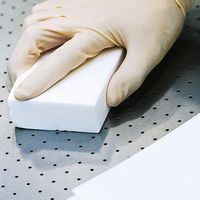

The sterile wipes PROSAT®Sterile™ Low Endotoxin consist of 100% ladder-proof polyester knitted fabric and are pre-soaked with a mixture of 70% IPA (USP grade) / 30% WFI water. Before sterilisation, the wipes are manufactured very cleanly to reduce endotoxin/pyrogenic contamination to an absolute minimum. They are the first choice for the pharmaceutical industry when it comes to sterile pre-saturated wipes. A high abrasion resistance is a further product feature. The edges are laser-cut and sealed.

Facts

Saturated wipes

Knit, 100% PES, with 70% IPA / 30% WFI, low endotoxin, validated sterile

Properties

- 100% polyester

- interlock knitted fabric

- saturated with 70% IPA/30% WFI water (IPA with USP cleanliness grade > 99%)

- validated sterile (SAL of 10-6)

- each batch has a guaranteed endotoxin level of less than 1 EU/device

- laser cut and sealed edges

- reclosable PE pouch, packed in a bag and outer bag

Advantages

- low particle and fibre emission

- abrasion resistant

- fast and efficient cleaning

- reduces the storage of cleaning agents

- easier to transport, store and use

- even application of the cleaning solution

Applications

- highly critical cleanrooms in the pharmaceutical industry

- for wet cleaning in sterile environment including process tools and other special equipment

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material (fabric) |

100% PES (no-run interlock knit) | |||

| Saturation solution |

70% IPA (USP grade) / 30% WFI (Water for injection) | |||

| Edge processing | Laser cut | |||

| Mass per unit area | g/m2 | 140 | ||

| Thickness | mm | n.s. | ||

|

NVR Non-volatile residues |

IPA based DI-water based |

g/m² g/m² |

0.01 0.01 |

IEST-RP-CC004.3, Sec. 7.1.2 IEST-RP-CC004.3, Sec. 7.1.2 |

| Particle residues | ≥ 0.5 µm | x 106/m2 | 2.6 | IEST-RP-CC004.2, Sec. 5.1 |

| Fibre Residues | > 100 µm | x 103/m2 | 0.142 | IEST-RP-CC004.2, Sec. 5.2 |

| Ionic Residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

0.18 0.003 |

IEST-RP-CC004.3, Sec. 7.2.2 IEST-RP-CC004.3, Sec. 7.2.2 |

| Sterilisation | validated sterile | SAL 10-6 | yes | n.s. |

| Guaranteed endotoxin level | Endotoxin Unit (EU)/wipe | < 1 | n.s. | |

| Dimensions | PU per lined case | Art. no. | ||

|

9" x 9" (~ 23 x 23 cm) 12" x 12" (~ 30 x 30 cm) 12" x 12" (~ 30 x 30 cm) |

550 pcs. (10 pcs./Pouch) triple bagged 450 pcs. (30 pcs./Pouch) double bagged 300 pcs. (10 pcs./Pouch) triple bagged |

59805 59805-01 59805-02 |

Note