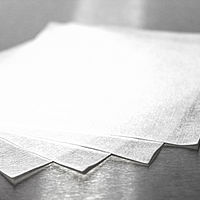

Series 304-1, a polyester-cellulose non-woven wipe, is versatile, both in microbiological controlled areas and in purely particle controlled areas. Although it is made of a non-woven fabric, the wipe has a certain abrasion and tear resistance (even when wet).

The cloth material combines the different strengths of cellulose (➜ absorbency) and polyester fibre (➜ abrasion resistance) and is therefore also a happy medium in terms of costs. The hydro-bonded non-woven fabric is not quite as clean in direct comparison to the series 300 and the series 302. In addition, the wipe has good chemical compatibility with different solvents and cleaning agents.

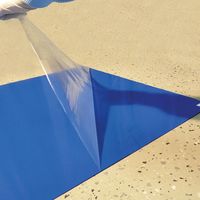

The blue dyeing enables the user to check how far a possibly aggressive liquid has spread in the wipe.

Facts

Polyester-cellulose

Non-woven, 45% PES / 55% CEL, blue dyed

Properties

- 45% polyester / 55% cellulose

- hydro-entangled non-woven fabric

- medium particle and fibre emission

- relatively abrasion resistant

- dyed blue

- good absorptive capacity

- double bag packaging

Advantages

- good chemical compatibility with different solvents and cleaning agents

- the blue dyeing makes it possible to see where a liquid (chemical) has spread

- multipurpose

- inexpensive

Applications

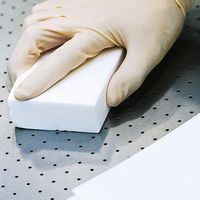

- all-purpose wipe

- absorbency of liquids and oily spills

- also suitable for cleaning tools

- workplace cleaning – especially for smooth surfaces

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 45% PES / 55% CEL | |||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 | 68 | ||

| Thickness | mm | 0.30 | ||

|

Absorptive capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | 5.2 344 | IEST-RP-CC004.3 | |

|

NVR Non-volatile residues |

IPA based DI water based |

g/m2 g/m2 |

0.221 0.101 | IEST-RP-CC004.3 |

| Particulate residues |

0.5 – < 5.0 µm ≥ 5.0 – ≤ 100 µm |

x 106/m2 x 106/m2 |

226 13 |

IEST-RP-CC004.3 Section 6.1.3 Biaxial Shake Test |

| Fibre residues | > 100 µm | fibres/m2 | 160,000 |

IEST-RP-CC004.3 Section 6.2.2.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

42 27 |

IEST-RP-CC004.3 Section 7.2.2.1 |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Size | PU/Carton | subpacked | Art. No. | |

|

4" x 4" 9" x 9" 12" x 12" |

14,400 3,600 1,500 |

12 bags à 1,200 wipes 12 bags à 300 wipes 10 bags à 150 wipes |

55304-1 0404 55304-1 0909 55304-1 1212 | |

| n. s. = not specified n. d. = not detectable |

Note