It is not easy to find the right gloves for particular tasks.

The material itself is not the decisive factor.

Our matrix of all glove variations gives you a better possibility to compare.

Cleanroom gloves differ from laboratory and surgical gloves in two essential points

Basically all 3 glove types are medical products, which use the Council (EC) Directive 93/42/EEC concerning medical devices (= MDD) and the Regulation (EU) for personal protective equipment (= PPE) as a basis for certification.

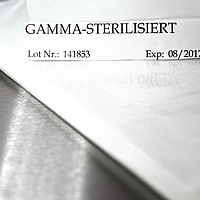

1. Documentation of cleanroom gloves

In addition to the required certifications, lot-related tests that are essential for cleanroom applications are also carried out, such as particle emission, endotoxin, ESD, residue values, etc. This applies to both sterile and non-sterile cleanroom gloves.

Note: In most cases, manufacturers' product data sheets only provide a rough overview. To obtain relevant data for an evaluation of a cleanroom glove, we recommend to request different certificates of analysis from different lots, if possible 3 or more.

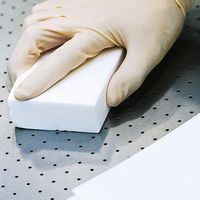

2. Further processing of cleanroom gloves after their manufacture

Up to a certain point, the laboratory, surgical and cleanroom gloves go through the same manufacturing process. Afterwards the cleanroom gloves are subjected to a complex post-cleaning process. This includes both chlorination processes and decontamination (washing) using DI water. Only the reduction of powder residues in chlorine baths is in many cases not sufficient to use the gloves in controlled conditions without hesitation. These two steps have a major influence on the characteristic features of a glove, such as purity, grip, conductivity, etc.

The packaging process then takes place, as with many other cleanroom products, under defined conditions. In many cases in cleanrooms of air cleanliness class ISO 4 or 5. But packaging under controlled conditions makes no sense without prior cleanroom-compliant preparation - i.e. decontamination. In this case, you would only have packaged a product in an ISO 4 or 5 environment - which is not the same as "suitable for use in an ISO 4 or 5 cleanroom".